loading article..

Date: June 1, 1974

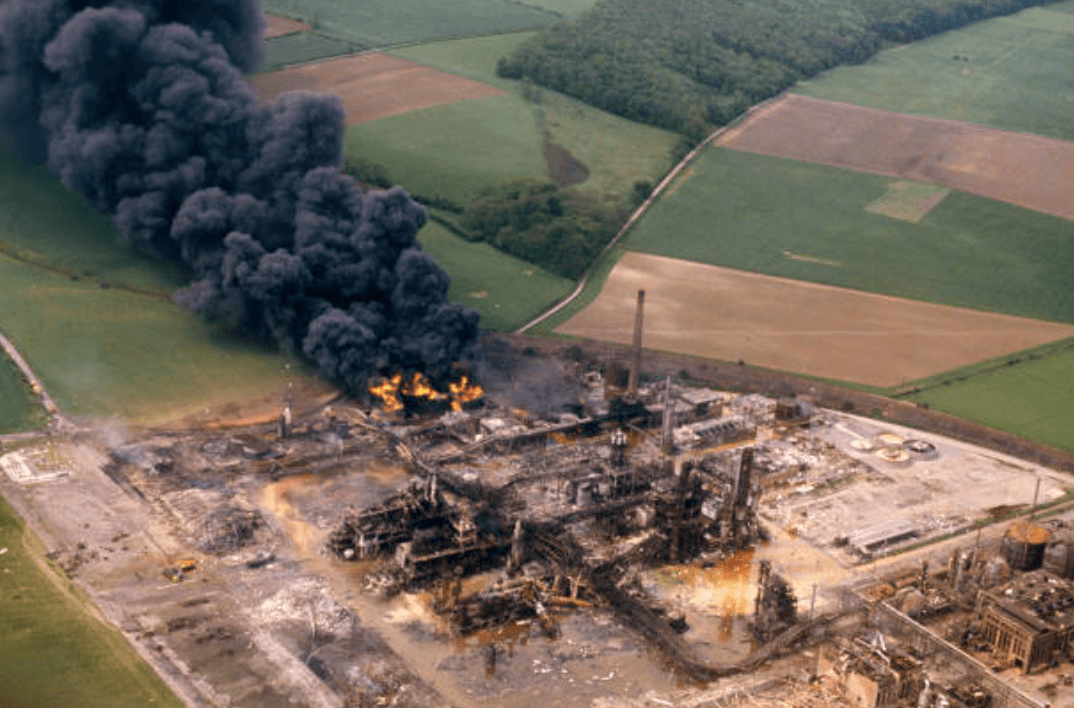

Location: Nypro (UK) Ltd, Flixborough, England

Fatalities: 28 workers killed, 36 seriously injured

Damage: Complete destruction of the plant and over 2,000 houses damaged in the surrounding village.

The Nypro chemical plant at Flixborough produced caprolactam, a key raw material for nylon, using a process that involved oxidation of cyclohexane — a highly flammable substance.

Cyclohexane was processed under high pressure (~150 psi) and elevated temperature (~150°C) in a series of six reactors connected by stainless steel pipework. The process had operated successfully for several years.

But when one reactor developed a crack, the chain reaction that would follow was not chemical — it was human.

In March 1974, a small crack was discovered in the No.5 reactor. To avoid a long shutdown, the engineers decided to bypass the damaged reactor by installing a temporary 20-inch diameter pipe — an improvised modification designed and fabricated on-site without proper engineering drawings or stress analysis.

This “dog-leg” pipe connected reactors No.4 and No.6. It was only meant to be a short-term fix until repairs were complete.

For two months, the plant continued to run with this modification.

For two months, the plant continued to run with this modification.

Then, on the afternoon of June 1, 1974, a massive vapor release occurred. A 20-ton cloud of cyclohexane escaped and spread across the site. Within seconds, it ignited — the resulting explosion was so powerful that it registered on seismographs 50 kilometers away.

28 people died instantly, the plant was obliterated, and hundreds of homes in the nearby village were damaged.

Unauthorized Modification: The temporary bypass pipe had not been properly designed or stress-tested. The support structure was inadequate, leading to fatigue failure due to vibration and pressure fluctuations.

No Drawings or Documentation: There were no formal engineering calculations, design approvals, or inspection records for the modification.

Inadequate Material Selection: The pipe material was not designed to withstand the thermal and mechanical stresses of continuous high-pressure operation.

No Leak Detection or Isolation Barriers: The system lacked real-time monitoring or emergency shutdown provisions to contain a large leak.

1. Lack of Competence: The plant’s senior chemical engineer — the one qualified to evaluate design changes — had left the company months before, and no one was appointed in his place.

Normalization of Deviation: “It’s running fine for now” became an accepted mindset. The modification worked for two months, reinforcing a false sense of safety.

Poor Management of Change (MoC): There was no formal process to evaluate or authorize design changes — an early lesson in what modern safety calls Process Safety Management.

Risk Perception Failure: The management underestimated the magnitude of risk associated with the temporary pipe — assuming it was minor, not realizing it had become the weakest link in the system.

The explosion changed the landscape of process safety forever.

The Health and Safety Executive (HSE) in the UK was formed in 1975 — directly influenced by the Flixborough disaster.

It led to the creation of the Control of Industrial Major Accident Hazards (CIMAH) regulations, and later the COMAH regulations.

It established the foundation for Process Safety Management (PSM) — particularly the Management of Change, Hazard Identification, and Mechanical Integrity pillars.

The Flixborough tragedy is more than an industrial disaster — it’s a reminder that engineering integrity and human behavior are equally critical barriers.

“A drawing not made, a calculation not checked, and a risk not imagined — that’s how disasters are born.”

This single incident became a turning point that shaped the DNA of modern process safety — from PSSR to MoC, from competence assurance to hazard reviews.

Health & Safety Executive (UK) – The Flixborough Disaster Inquiry Report (1975)

Institution of Chemical Engineers (IChemE) – Case Studies in Process Safety

U.K. Chemical Safety Board Archive