loading article..

It was a cold December night in 1984. At the Union Carbide pesticide plant in Bhopal, India, the air was heavy with the faint odor of chemicals. Inside the control room, the pressure gauge on the Methyl Isocyanate (MIC) tank began to climb. By the time the operators realized what was happening, the reaction had already begun — unstoppable, unseen, and unimaginable.

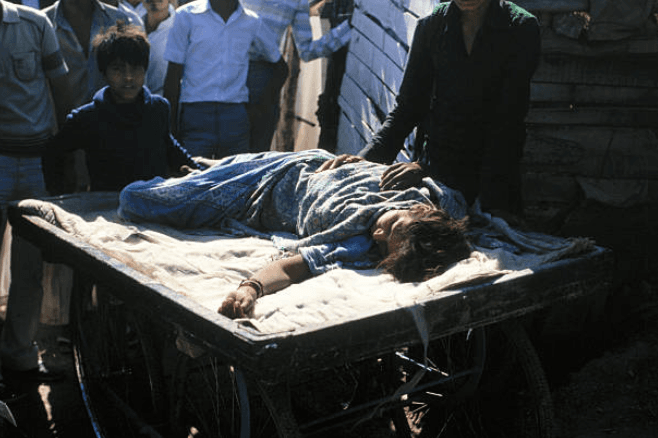

Within hours, a toxic cloud blanketed the sleeping city. People woke coughing, gasping, blinded by burning eyes and lungs. By dawn, thousands lay dead. The Bhopal Gas Tragedy became the world’s worst industrial disaster, claiming over 3,000 lives immediately and affecting half a million more in the months to follow.

The plant was storing large volumes of highly toxic MIC, far exceeding safe capacity. To save costs, key safety systems — the refrigeration unit, flare tower, and vent scrubber — were switched off or under-maintained.

When water leaked into one of the storage tanks, it triggered a violent exothermic reaction, causing the tank to rupture and release tons of deadly gas into the night air.

This was not one big mistake — it was a chain of small ones, woven together by complacency.

The Bhopal Gas Tragedy stands as a timeless warning: safety isn’t just a technical system — it’s a moral system.

When cost, convenience, or complacency outrun conscience, tragedy follows.

Bhopal changed the world’s understanding of process safety. It gave birth to modern frameworks like Process Safety Management (PSM), Responsible Care, and community right-to-know laws.

But even today, its echoes remind us — every safety valve we test, every alarm we check, every question we encourage is a tribute to those who suffered that night.

Because in safety, what we do every day determines whether another Bhopal will ever happen again